Kinsler Extruded Aluminium Fuel Rail

Extruded aluminium fuel rail material in bulk form. Our extrusion design allows for the drilling and tapping of 8 AN female o-ring end ports (NO pipe thread which can crack the tube, or sealer compound to get in your fuel system).

Available in 3 different sizes

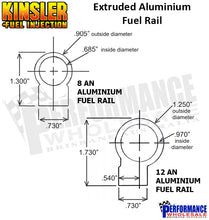

Extruded aluminum fuel rail tubing, 6061-T6 alloy, .680" I.D., .110" wall, .900" wide x 1.3" tall

-8 (.685" or 17.4mm i.d) 24" long (60.98cm)

Extruded aluminum fuel rail tubing, 6061-T6 alloy, .970" I.D., .140" wall, 1.250" wide x 1.730" tall

-12 (.970" or 24.64mm i.d) 24" long (60.98cm)

-12 (.970" or 24.64mm i.d) 32" long (81.28cm)

Kinslers 8 AN fuel rails with .685” ID are more than adequate for most applications. Our 12 AN fuel rails with .970” ID have twice the crosssectional area of the 8 AN rails... we recommend these for very high horsepower gas engines, most methanol engines, systems with very large injectors, or two injectors.

The problem: When a very large EFI injector is pulsed (opened), it takes a very quick “gulp” of fuel out of the rail, causing a large instantaneous pressure drop. These pressure drops can reinforce each other in a random ram tuning within the rail and attached fuel hoses that cause chaotic pressure pulsing; we have seen plus and minus 30 psi on a 130 psi supply (100 - 160 psi range). As the pressure waves travel through the fuel rail, some injectors are likely to open when there is a high or low local pressure... this causes very significant cycle to cycle rich and lean conditions to the cylinders, as once the injector opens, it’s simply a function of the pressure acting on it’s outlet orifice(s). A pressure gauge will not respond accurately to these pulses as they are too fast; we use very fast response piezoelectric pressure transducers to analyze these systems.

Why the larger rails help: All fuel has some air in it, especially after the system has run a little, because the return fuel absorbs more air as it falls back into the tank. This makes the fuel a bit compressible, thus the larger rail assists the ability to take a “gulp” with less pressure drop. Kinsler have seen 45 horsepower picked up in some applications by just switching from the 8 AN to the 12 AN rails.

Avoid using individual supply hoses to the injectors; they cause huge pressure drops because of the pulsing flows. If you must use them, make them all the same length, and as large an ID as possible... 3/16” ID is too small; 3/8” would be much better