Boundary Racing Pumps

SHOP NOW

About Us

Founded

Boundary was founded in 2003 and specialized in producing various metal goods for the automotive racing industry. Boundary has been dedicated to producing exceptional products exclusively for the automotive racing industry. As early as 2004, we began researching and understanding the complexities of manufacturing gear pumps commonly used in the automotive racing industry. By 2005, we proudly unveiled our inaugural line of gear products. With thousands of our top-tier pumps sold, our units have demonstrated unparalleled success in engines producing up to 550hp/L.

Cutting Edge Technology

Boundary remains at the forefront of technological advancements, employing cutting-edge CNC milling and turning equipment to craft our products. Our high-end American made machining centers, along with expert personnel, ensures the utmost precision necessary for the seamless functioning of inter-meshing gear pumps.

American Made

Boundary oil pump assemblies are manufactured in our in house facilities in Dallas, TX. It is our internal capabilities that afford us the consistency and unmatched quality that cannot be found elsewhere.

Increasing Focus

Unlike other manufacturers who spread their focus across a myriad of areas, our company is solely dedicated to lubrication systems. We take pride in specializing in this specific field, allowing us to deliver the highest-quality lubrication equipment tailored to meet your high-performance needs.

new patented dual gerotors push 30% more flow and pressure into your engine, delivering huge increases in engine endurance, and accessory control like vvt. Starting on the Toyota Supra , but coming to many models! #BoundaryPumps

new patented dual gerotors push 30% more flow and pressure into your engine, delivering huge increases in engine endurance, and accessory control like vvt. Starting on the Toyota Supra , but coming to many models! #BoundaryPumps

MartenWear Heat Treatment

MartenWear heat treatment for ultra-long wear debris resistant surfaces

Our MartenWear process developed and applied all in house is a 2nd stage of heat treatment to our billet components. MartenWear heat treats the exterior surface of the part to be extremely hard and long wearing. This surface is more robust against debris ingestion and has been found to be wear free in all applications up to and beyond 13000 RPM. This process is available for most of our steel billet components.

Specification:

- Vickers; 620 – 720

- Rockwell C: 55 – 60

- Maximum Tested RPM: 13,000

- RPM Limit: Unknown

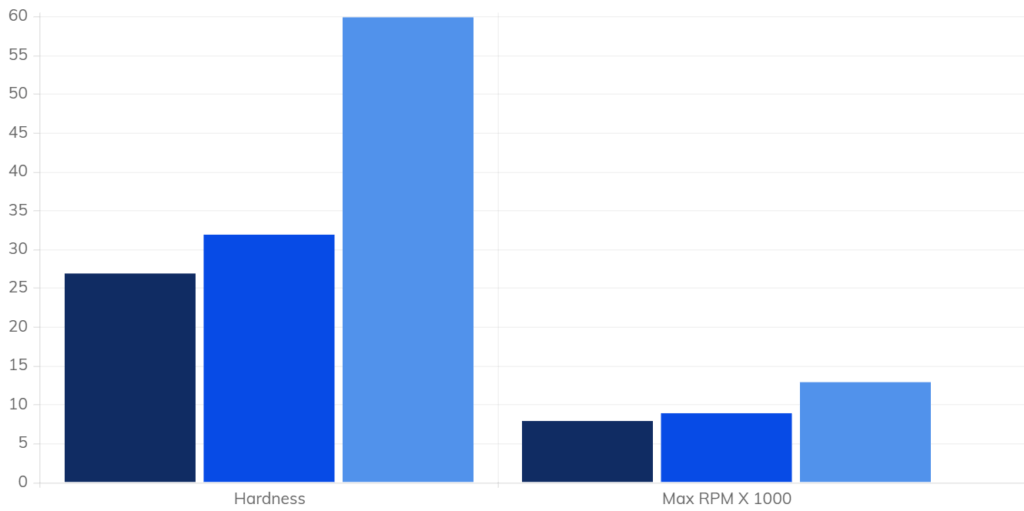

Hardness of Gear surfaces in Rockwell C

Hardness of Gear surfaces in Rockwell C