Valvetrain Stability: Making The Switch To Shaft Mount Rocker System

Following the introduction of the overhead valve production engine, it was quickly followed by those who appreciated the engineering advantages and wanted to begin squeezing out more power. The innovative pushrod-based valvetrain was augmented with more aggressive cams and stiffer valve springs as the original go-fast hardware.

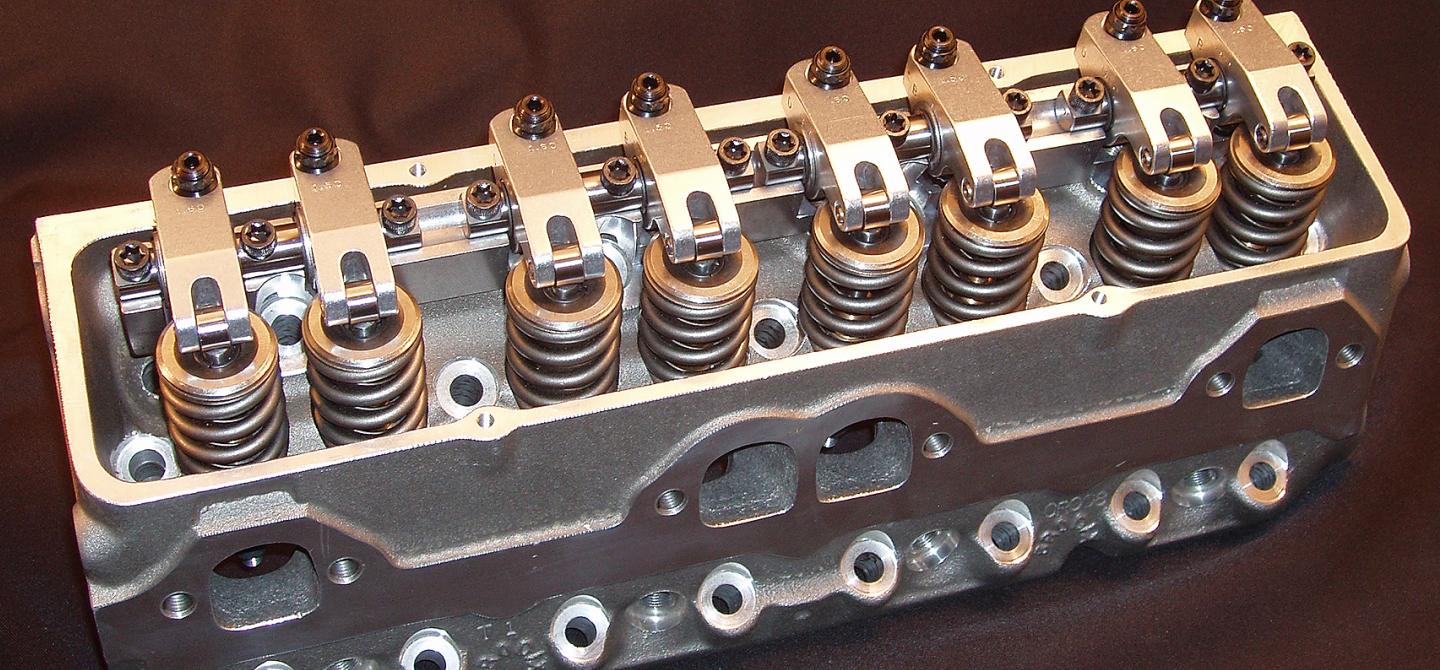

As time and performance progressed, improved roller rocker arms, screw-in rocker studs, and even stud girdles offered more reliability for these more aggressive cams.

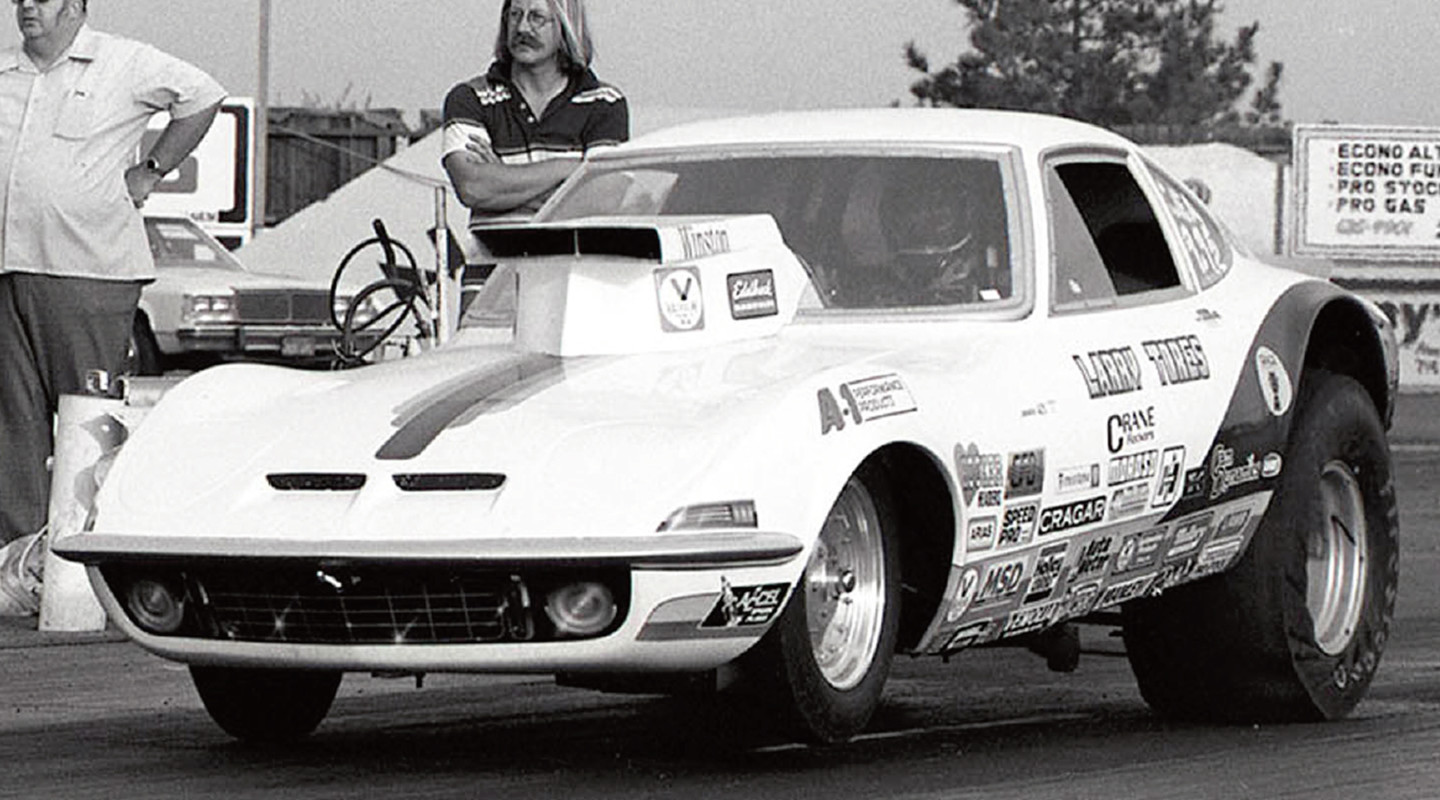

Approximately 45 years ago, Larry Tores was a competitor in Stock, Super Stock, and Competition Eliminator classes, which relied on horsepower based on high-rpm engines. This motivated Tores and his fledgling company, T&D Machine Products, to develop his shaft rocker arm system to battle valvetrain reliability issues.

.

We dove into the engineered advantages of a shaft rocker system with Sheldon Miller and Phil Elliot from T&D Machine Products to gain some knowledge on the basics and benefits.

Rocker Arm Necessity and Invention

Though the stud and roller rocker arm system still provide a wealth of performance benefits, the strength and stability provided by the shaft rocker arm system offer significant options. Not only can you meet the demands of the most extreme racing engines, but choices now include cost-effective sets for all levels of horsepower.

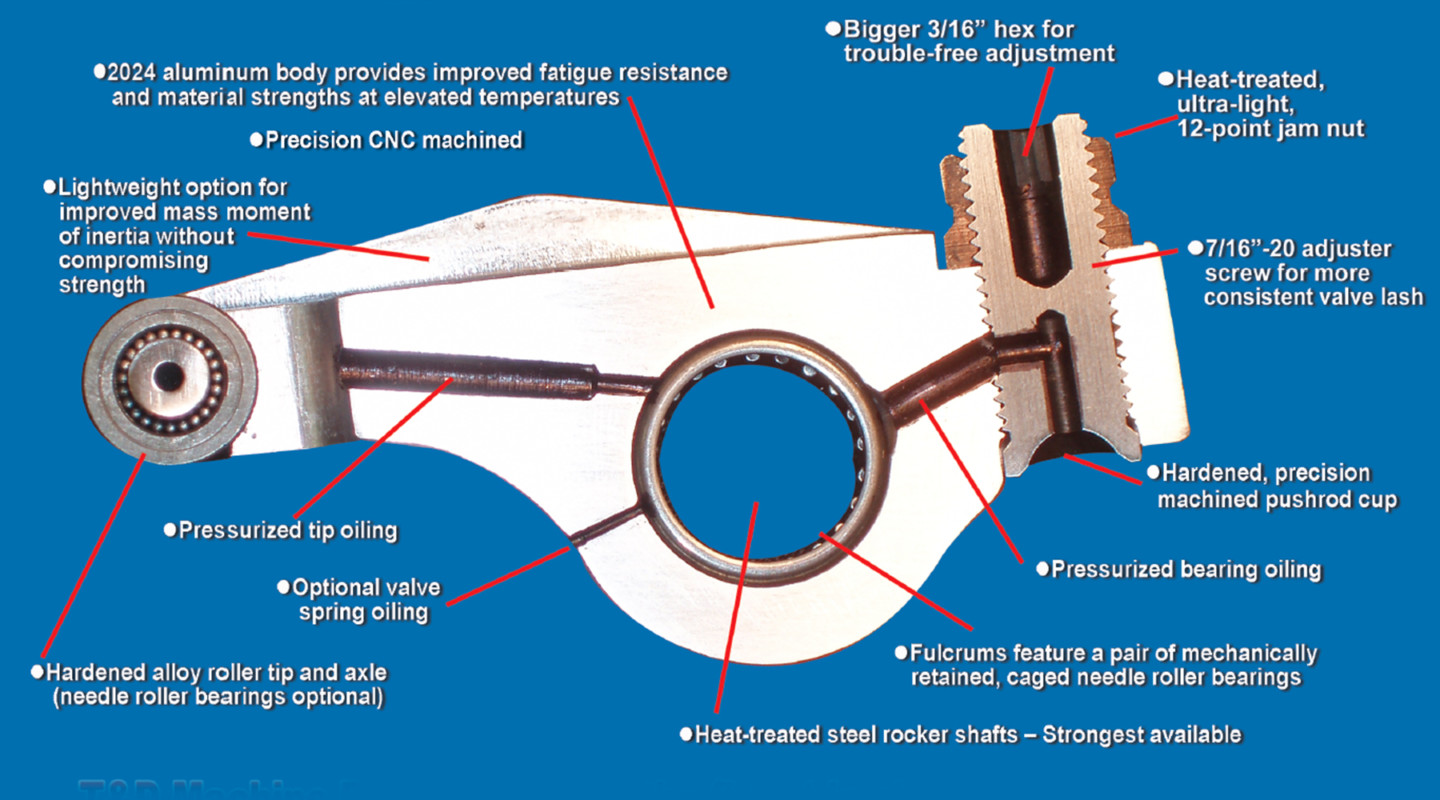

The pivot point of the rocker arm is called the fulcrum. The rocker arm ratio is the measured difference between the fulcrum and the pushrod (Y) and to the valve tip (X). Another critical option in racing engines is the rocker offset. This top view illustrates different offset rockers based around a cylinder head with larger valves and other geometry changes.

.

Thought to be too expensive for street/strip or bracket racing engines, every rocker set T&D manufactures is designed with a specific application in mind. Miller explains, “On our stock-style big-block Chrysler rockers, we use a shaft with far less deflection than the factory shaft. The system is designed for years of service, even in street applications.”

Where Stud Rockers Leave Off

With rocker arm studs screwed into your heads, you have a set pivot, or “fulcrum point,” between the pushrod cup and tip of the valve. The overall length of a rocker arm is called the “pivot length.”

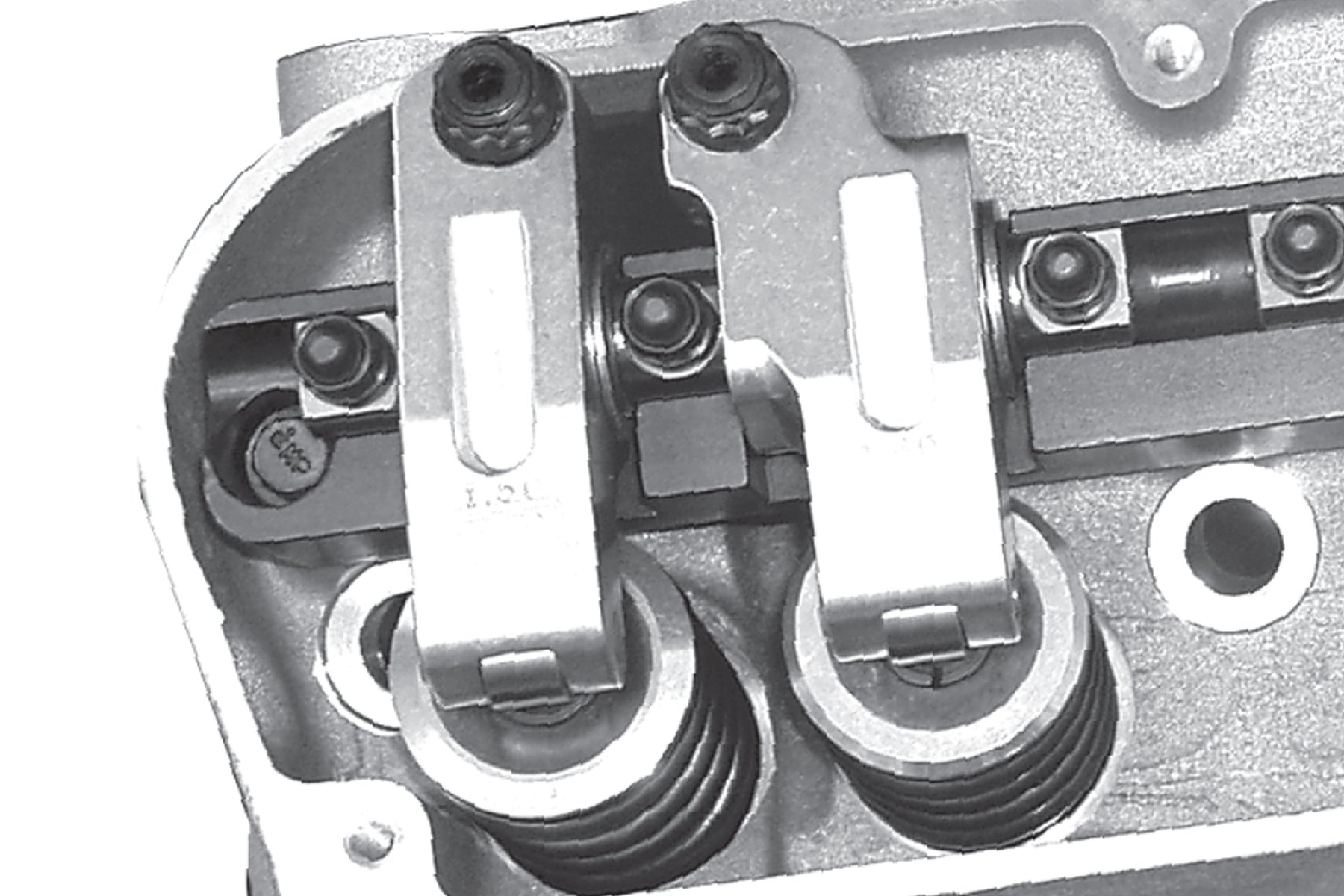

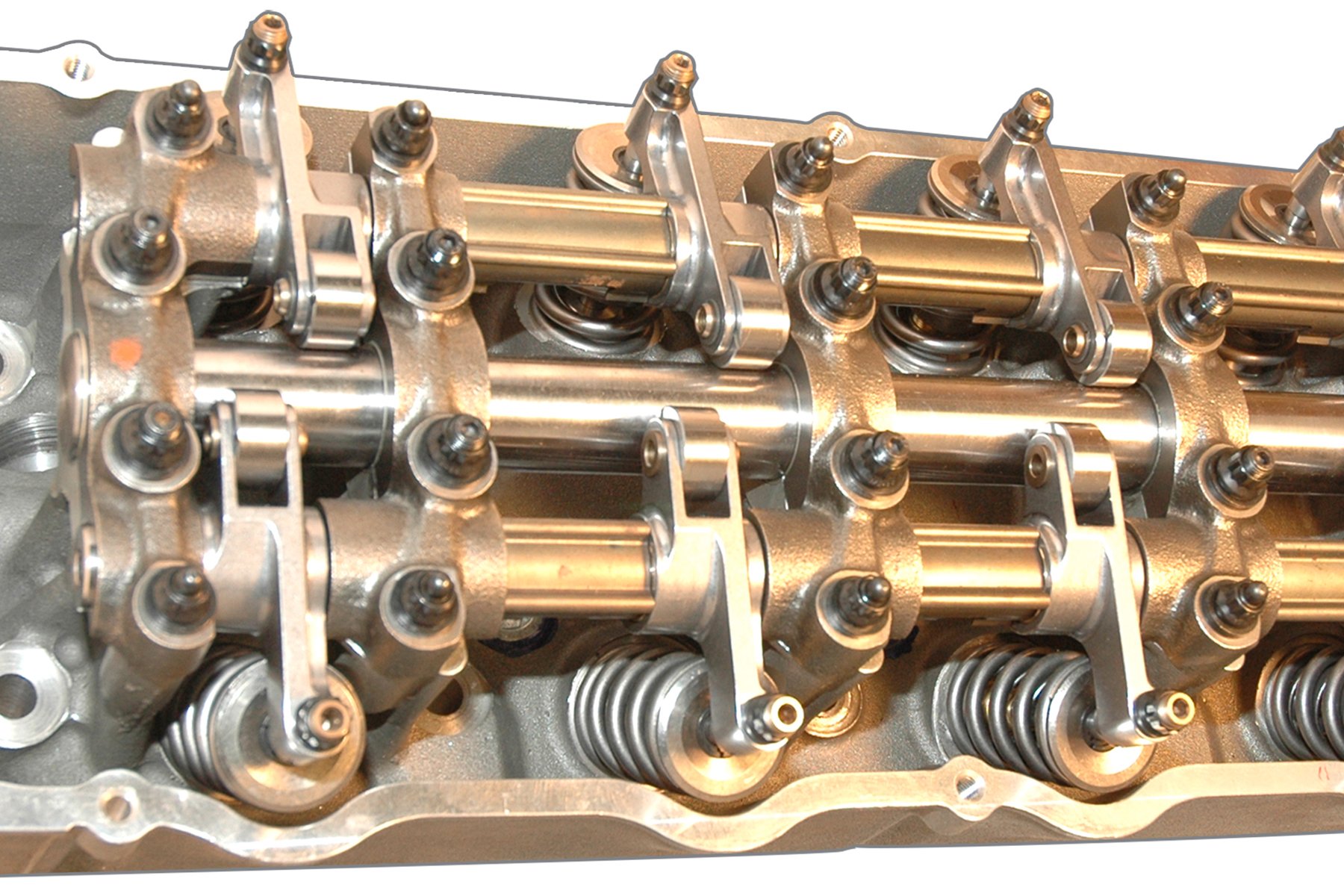

Without the rocker stud mounted through the centre of the rocker arms, this cutaway-view illustrates some of the many benefits of a shaft-mount rocker. The large roller bearing at the fulcrum and the adjustability of the valve-lash at the pushrod cup offer strength benefits.

.

One might consider that the valve lift from your racing cam is one of the determining factors between a stud and rocker system and shaft rockers. Elliot explains, “It is better stated in the opposite way: a rocker arm can affect cam lift. The lift at the valve can be altered by changing the ratio of the rocker arm. To make a camshaft “look bigger,” the rocker ratio is increased, and therefore, increases the valve lift.”

Altering rocker geometry is limited with screw-in studs. Altering rocker geometry is limited with screw-in studs. You can only modify the installed valve height by changing the engine’s pushrod length.

Still, short of moving that fulcrum point with a different cylinder head design, the overall rocker arm pivot length is finite.

"The fundamental shaft rocker uses a solid shaft, two mounting points, and a solid rocker arm without the need of a stud mounted through the centre; racers can experience benefits in strength and longevity at horsepower levels just 10- to 20-percent above stock. – Sheldon Miller"

Geometry Game Changer

The game-changer for the T&D designs is the stand system that mounts to the cylinder head. These stands support each rocker arm with an entirely different design compared to a rocker stud. By eliminating the stud, the rocker stand can alter the fulcrum point for the rocker arm in ways the stud cannot, thus providing much more opportunity for varied rocker arm ratios.

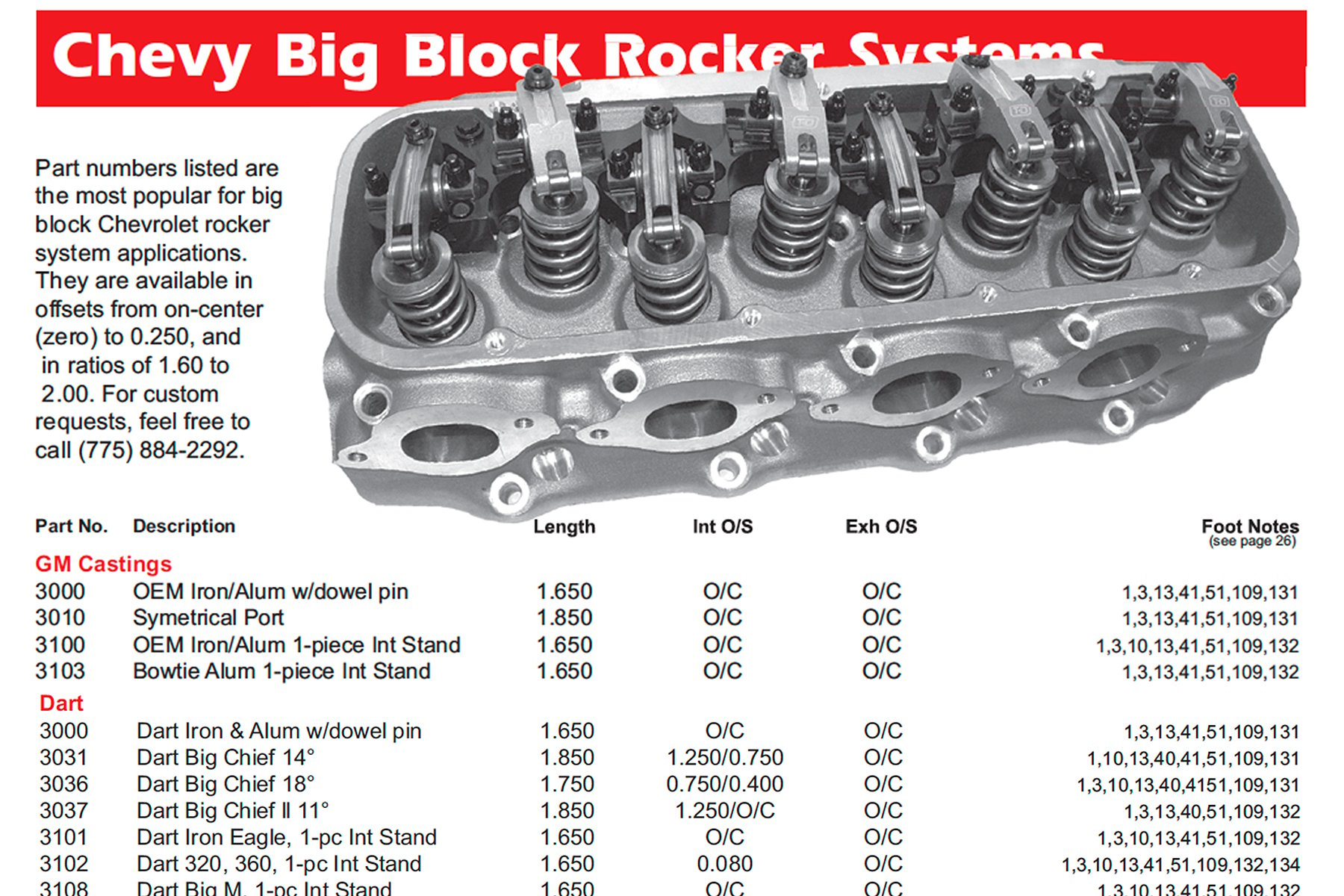

The vast selection of shaft rocker systems available within the T&D Machine catalogue illustrates the wealth of different rocker arms available in varied designs. For example, the dimensions available for different big-block Chevrolet head designs can range from a 1.650-inch to a 2.150-inch overall rocker length.

.

If you think you might have a unique rocker arm ratio or offset situation, it’s pretty safe to say that T&D has been there and done that. It will work with customers and their applications to engineer the proper geometry.

To cruise the T&D Machine catalogue is to view the wide variety of rocker arm ratios, overall lengths, and offsets for a given cylinder head. T&D Machine also offers its shaft systems for ultra-unique heads, such as the vintage Ford SOHC cammer.

.

“In many cases, the fulcrum ratios of the rocker arm, combined with the amount of offset, will limit how much ratio we can design into a given application,” Miller describes. “There are limits with the fulcrum length compared to the overall rocker ratio. When changing to a longer rocker, we must also change the stand to keep geometry or tip placement properly located. We do that all the time for customers.”

Length, ratio, and offset options are only a portion of the shaft rocker system advantages. The fundamental design of one cross shaft allows for many strength benefits. Not only is the rocker assembly supported by two bolts on each side, by eliminating the stud through the centre, beefier roller bearings are featured inside of the rocker arm.

"Most engine builders find that because lash settings remain so consistent with shaft rockers, they can diagnose engine problems such as stretched valves and sunken valve seats, before catastrophic failure occurs – Phil Elliot"

To adjust the valve lash in a stud rocker, the adjusting nut is located at the fulcrum pivot. T&D rockers use a large 7/16-inch adjuster screw at the pushrod cup. This adjustable cup uses heat-treated alloy steel material and a broaching process for longevity.

Materials

The materials and machine processes utilized by T&D are held reasonably close to the chest. Though general materials are described, the T&D shop undergoes a constant flux of the latest in machining equipment and product R&D.

“After years of testing and development, we settled on 2024 aluminium for our standard rockers,” says Miller. “It provides the best combination of strength at elevated temperatures and fatigue resistance. Our steel rockers use a 4130 material because it handles the rigors of extreme racing applications just as well as exotic steels, but at a fraction of the price.”

“As for our hardcore race sets, we design the stand as rigid as possible, to supply as stable a platform for the rocker to operate from,” Elliot explains. “It is not unusual to add extra bolt locations in the head to keep things from moving around at high rpm.”

.

Elliot expands on the machining methodology within T&D’s shop.

“The tolerances to which we machine our components haven’t changed over time. Some things are non-negotiable. The speed at which we make them has increased. As demand has grown, we have continuously upgraded how we make our parts.”

T&D developed its SportComp shaft roller rockers to be comparable in price to the highest quality grouping of stud rocker components. On the other end of the spectrum, they have developed ultimate designs for extreme horsepower levels and endurance applications.

.

Match Your Application

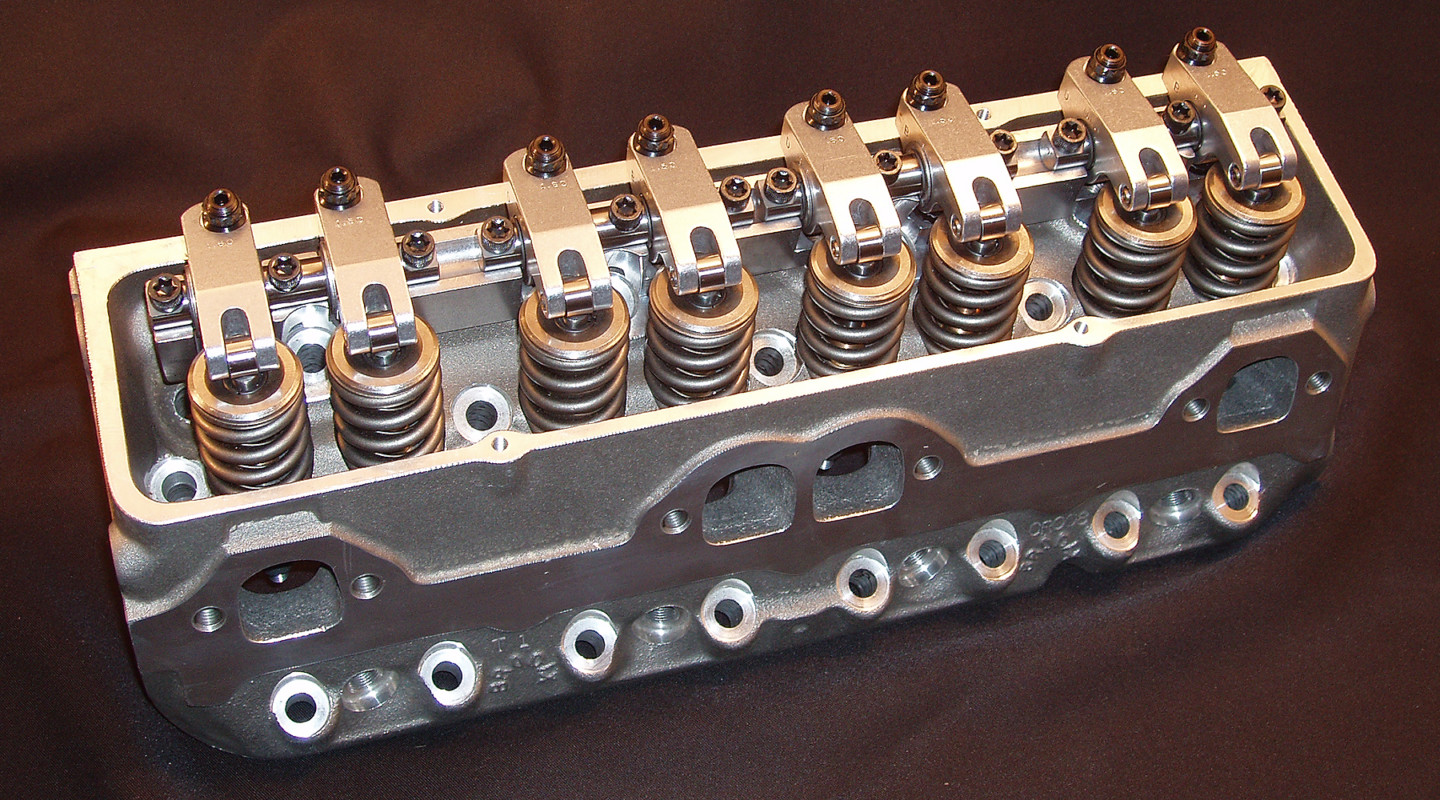

Whether you need a bulletproof rocker arm system or a reliable set of rockers for sportsman racing, there are many levels of shaft rocker arms to match your application and pocketbook.

There are many options within the T&D shaft rocker lines. The standard aluminium rockers offer cost-effective shaft systems. The lightweight rockers offer strategically removed material for a reduction in mass. The latest steel rockers offer greater strength and minimum deflection in highly-boosted engines.

.

Replacing aluminium with the steel rocker arm option, these ultimate rockers decrease deflection and are engineered with rocker arm weights within a few grams of the aluminium versions.

Strength and durability have become more of a consideration with racers of all levels. When the experience of a failed rocker arm damages cams, pushrods, and even valves and pistons in some cases, raising the bar when considering your valvetrain choices such as rocker arms is an exercise in paying for strength now, rather than repairs later.

T&D Rockers are available from Performance Wholesale Australia

Contact our sales team on 07 3808 1986

Credit: Dragzine

MAY 18, 2020