CP-Carrillo Tech Talk - Part 3

Do you know why some pistons have what is referred to as a “donut dish” while other have a normal flat bottomed dish? On engines where a very large stroke is used or a long connecting rod is being utilized to maximize rod to stroke ratio the compression height can become very short. When you have such a short compression height this places the wrist pin end of the connecting rod very close to the underside of the piston crown and sometimes there is even a relief cut needed on the underside. To make sure that the crown thickness of the piston in this area remains a uniform thickness with adequate strength a bump out is added in the middle of the piston dish. This bump out makes the dish look like a donut hence the term “donut dish.”

#themoreyouknow #cpcarrillo #cppistons #carrillorods #ariaspistons #donuts #engineering #performance #precision

________________________________________________________________

.

Stretch vs. Torque?

At CP-Carrillo we are asked constantly what the assembly torque specification for our bolts is. While torque is a relatively easy and fast way to assemble non-critical engine components, a higher degree of precision is required when assembling a connecting rod.

When assembling a connecting rod we are not merely putting two pieces of metal together, no there is much more going on. Specifically there are two things we are focused on; bearing crush and clamp load. Correct bearing crush is achieved when sufficient clamp load is applied. If too little clamp load is applied the big end bore of the connecting rod can distort and cause premature bearing or bolt failure.

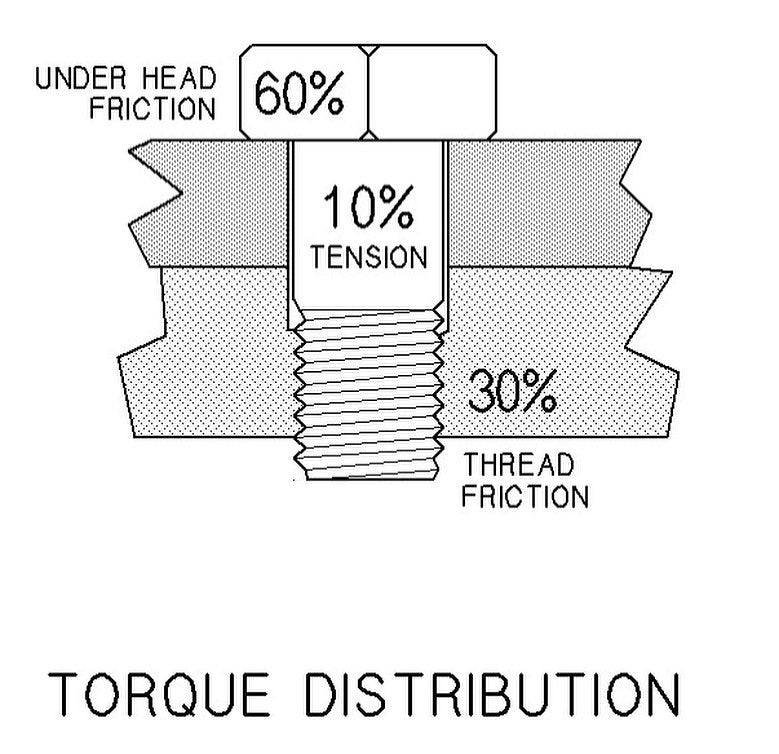

So with clamp load being so important how do we insure that proper clamp load is applied? The answer is stretch. At this point many people would say “hold on there, because doesn’t torque tighten enough?” Most of the torque applied to a fastener is absorbed overcoming friction forces in the threads and the surface area under the fastener head. This results in a accuracy of +/-25% and depending on lubricate and cleanliness can be far worse. Tightening a fastener through elongation (stretch) results in a much more satisfactory +/-3% accuracy.

So why do we need to be so accurate? To achieve the maximum clamp load we need to stretch the bolt to its proof load. If we stretch the bolt too much we both yield the bolt and distort the bore housing, too little and we do not achieve enough clamp load to keep the split line of the connecting rod closed under engine loads.

Always refer to the Carrillo bolt instruction sheet when determining how much stretch to apply to your bolts.

Remember torque is for burning rubber, not your bolts!

#themoreyouknow #cpcarrillo #carrillo #carrillorods #fasteners #bolts #friction #stretch #clampload #precision #engineering #performance

________________________________________________________________

.

What Are pin buttons?

A “button” is a method of pin retention. Many of you are familiar with locks whether they be wire or spiro-locks and how they are used in order to hold the piston pin in place. In high horsepower applications such as top fuel and blown alcohol, a button is the most common method used to hold the pin in the piston. And while we do have the capability to use locks even in some of these high power applications in order to save weight; the button is often still preferred as it allows quick disassembly and reassembly between rounds which can be difficult with locks. Buttons are also responsible for supporting the oil ring, but in some severe applications can be used in conjunction with a rail support to prevent “waffling” of the oil ring which occurs when a button tries to rotate and “beats up” the oil ring. Whatever your application or preference CP Carrillo has you covered.

#themoreyouknow #cpcarrillo #cppistons #pistons #buttons #performance #engineering #allinthedetails #wegotyoucovered

________________________________________________________________

.

Did you know…. before our piston skirt coating can be applied the piston must be cleaned and chemically prepared. We wash the pistons through a series of machines. Closely monitored and proprietary processes ensure cleanliness, consistency and proper adhesion of the coating. We also perform inspections and adhesion tests on said coating to ensure it meets our standards and withstands durability requirements.

#themoreyouknow #coatings #cpcarrillo #cppistons #ariaspistons #clean #prep #precision #engineering #itsallinthedetails

________________________________________________________________

.

Did you know at CP-Carrillo we use Rapid manufacture prototyping...

This allows CP-Carrillo to have multiple options in manufacturing and design.

In manufacturing we can design and conceptualizing various fixture before investing capital. Just a few examples of fixtures: CMM adapters for Rod OEM, Threaded plugs, orienting fixture.

In design, we have the ability to rapid prototype, using 3D printing, entire rotating assemblies, PCU (power-cell units) assemblies, and highly detailed piston concepts. For product meetings and concepts.

#cpcarrillo #fromconcepttoreality #rapidprototyping #engineering #design #production #3dprinting #themoreyouknow #flexibility #ariaspistons

________________________________________________________________

.

Did you know that Oil Support Rails (OSR) assist in applications where the pin bore breaks through the oil groove of the piston (e.g. short compression heights due to big strokes or long rod lengths). Without it, the oil ring would come off the ring groove through the wristpin opening. OSR have dimples that stop them from rotating thus working as a “bridge” for the ring. These dimples ALWAYS face down and Oil support rails should under no circumstances touch cylinder walls.

________________________________________________________________

.

When buying turbo pistons or upgrading piston pins, heavier is not always better.

“If I have a turbo, better just buy the strongest, heaviest piston and pin they have and then I’m covered for anything, right?” Although you do want strong enough parts for the power and usage that you have planned, what we are finding is that too many times customers are over-buying for their builds and actually causing premature wear, loss of power and revs, and spending more when they could have used the money elsewhere. Here, I would like to explain why purchasing heavy duty pistons or upgrading pins good for 1600HP when you are only ever going to see 800HP can actually be a bad thing.

1) Crank balancing. Heavy piston assembly (piston, pin, locks, and rings all weighed together) = more weight must be added to the crank to run properly.

2) Can limit max RPM and slow rev speed. At RPM, grams turn into pounds. Imagine those extra pounds of weight your crankshaft is trying to rotate, it can not only limit the rev speed of your engine and peak power/RPM, but put extra stress on other components.

3) Stress and wear on the pin bores. Although detonation and insufficient oil getting to the pins are also causes, extra heavy pins in the piston can also oval out the pin bores over time. Problems with ovaling out pin bores include the clearance continues to increase and can eventually fatigue the pin boss area and initiate cracks, or in bad cases it can pop a wire lock out and the pins walk out the door.

When we design a piston for a high HP and/or RPM, we keep extra material in the pin boss for more pin engagement, and we also add more material and design underneath the pin bore in what is called the tang, or slipper to support more weight and stresses.

4) Stress and wear on rods and rod bearings. Rods not only need to be designed for your max HP, max RPM, and all the drifting, drag racing, or endurance road racing abuse that you have in store for it, but also for the force loads that piston attached to it is going to enact. Think about shoulder pressing a dumbbell, more weight equates to fewer reps and quicker fatigue (unless maybe you’re The Rock)

Same goes for the rod bearings. Yes, that tiny sliver of metal between the connecting rod big end and your crankshaft has to support all the weight of everything on top of it. Any weight you can take off the rotating assembly helps the bearings last longer.

5) Extra clearances where it may not be needed. Heavier duty pistons can use looser clearances to allow for the high cylinder pressures and heat from large turbos. If you install these kinds of parts with the clearances they are recommending in an engine not seeing those same pressures, you may end up with some piston slap, louder cold starts, and/or potentially higher skirt and cylinder wear.

6) Extra Cost. Often with “high horsepower upgrades” comes a higher price tag.

All this is not to say that people should not be upgrading to stronger piston designs and stronger pins when needed. But with this knowledge you can hopefully avoid purchasing a piston and/or pin that is just not right for your build. Where another manufacturer may want to just sell you every expensive upgrade they have, at CP-Carrillo we want to ensure you are getting the perfect product for your build.

So where do you go from here?

The first question you should ask is “What is the max horsepower you want to achieve with your build?” But also try to be realistic. If everyone else is making 600hp with the turbo you just bought, don’t ask for a 1200hp piston assembly.

CP-Carrillo offers an HD line of many popular engines including: Honda B-series and K-series, Toyota 2JZ, Nissan GTR, and Mitsubishi 4G63, but these pistons were designed for about 225-350hp PER CYLINDER, so they are quite heavy. However I would not recommend these to someone making low boost because of all the reasons above.

Regarding pins, be careful not getting a super thick pin if you don’t need it. We are happy to recommend a pin to you based on your power goals. We offer numerous thicknesses and multiple upgraded materials depending on your needs. Contrarily, if you are making big power, you can also check to make sure the pins supplied with your parts are sufficient for your goals. When in doubt, best to check it out.

#themoreyouknow #cpcarrillo #cppistons #pistons #pins #heavyduty #weightmatters #performance #engineering

________________________________________________________________

.

Did you know design flexibility is one of the most important things at CP-Carrillo? What we learn from our extensive OE involvement allows us to take piston and rod designs to new levels and share that directly with our customers. Our vision for future designs entails all related components, designing the piston, rings, locks, wristpin and rod all around each other, ensuring you get the best piston-rod assembly the industry has to offer, a feature no other manufacture can claim.

#cpcarrillo #cppistons #pistons #carrillorods #connectingrods #rods #proud #quality #engine #engineporn #horsepower #highperformance #cargram #bestinthegame #madeintheusa #becauseitmatters #thechoiceconnection

________________________________________________________________

.

Did you know… anodizing is not traditional coating? Nothing gets added, sprayed or baked onto the part. Nothing can peel or chip.

Anodizing is created by converting the surface aluminum into aluminum oxide. This forms an extremely durable, hard, abrasion resistant and long lasting layer.

The process is called anodizing because the piston being treated forms the anode of an electrolytic cell. Parts are surrounded by sulfuric acid and exposed to a relatively low – voltage DC current.

Most of our OEM pistons get Type III hard anodized inside the compression ring groove for wear resistance. All of our top fuel pistons are entirely Type III anodized to withstand the abuse in the most extreme form of racing.

#cpcarrillo #cppistons #type3anodizing #hardanodizing #pistons #coatings #themoreyouknow #precision #engineering #ariaspistons

________________________________________________________________

.

One of the most over looked and misunderstood measurements of the engine is Piston Ring end gaps.

Let’s briefly explain the purpose of each ring:

The top ring is typically barrel faced and has positive twist, due to the bevel on the inside of the top of the ring. It is commonly known as the compression ring. Its main job is to keep combustion gasses in the combustion chamber. The 2nd rings are designed to scrape oil, controlling most of the oil film on the cylinder wall. The Oil ring consists of two rails and a vented oil ring expander which provides tension and oil drain back to the crank case. Used in conjunction with the 2nd ring for overall oil control, the tension on oil rings vary based application and engine oil systems. The most common type of oil ring is a 3 piece oil ring, but 2 piece oil rings are becoming more and more popular.

We see a lot of pistons that fail because of tight ring end gaps. If there is not adequate end gap on the 2nd rings they will butt and you will lose the oil control, which floods the area between the top and 2nd ring with oil and eventually causes the top ring to lose ring seal and leads to detonation.

CP Carrillo generally recommends larger end gap on top and 2nd rings than the other companies in the industry, this is a safety precaution, assuming the worst engine running conditions. It gives the end user a wider tuning window, because a little extra is better than not enough.

CP Carrillo recommends .008” to .010” more end gap on the 2nd ring than the top ring. For instance, if your bore is 4.030 and you are running the top ring end gap at .024”, then your 2nd ring end gap would be .032 to .034 based on our .008 to .010 more recommendation. This is a minimum recommendation and can be more, if engine conditions require it.

Filing ring end gaps correctly is just as important as the gap itself. After you file the ring, hold it in front of a light and compress ring with your hand and you see if it’s square or not. Use a stone to remove sharp filed edges, then install it in the bore and use a feeler gauge or other similar device to check end gap.