Inside Ford Performance’s Gen-3 Aluminator 5.0-Litre Engine

.

Usually, when you are considering a crate engine, it’s because you want a ready-to-go solution for whatever project you might be working on. You don’t want to have to build an engine from scratch, or as in the case of a Gen-3 Coyote, buy a core engine and change it into what you want. However, when an engine is as new as the Gen-3 Coyote, you’re not faced with many, if any, off-the-shelf options… Until now.

The Ford Performance Aluminator concept has been around for quite a while — well before the Coyote was on the scene. The idea being that, regardless of what specific form of automotive enthusiasm you enjoy participating in, the Aluminator will work for you as a solid foundation for you to build upon. Whether you want to build a turbocharged drift car, a supercharged drag car, or a naturally aspirated corner carver, the Aluminator will happily perform the task.

Curious as to what recipe Ford Performance follows to build such a powerplant, we decided to dive into the production of the engine from start to finish. As a special treat, we didn’t just follow any engine through the specialty assembly process, but serial number 0001, destined for the engine bay of our sister title’s (Ford Muscle) Project F-Word F100 pickup truck.

The Gen-3 Aluminator took some time to come to market due to internal reorganization at Ford Performance, but the wait was more than worth it. This iteration of the Aluminator is the highest performing 5.0L ever to wear the name.

Inside The Belly of the Beast

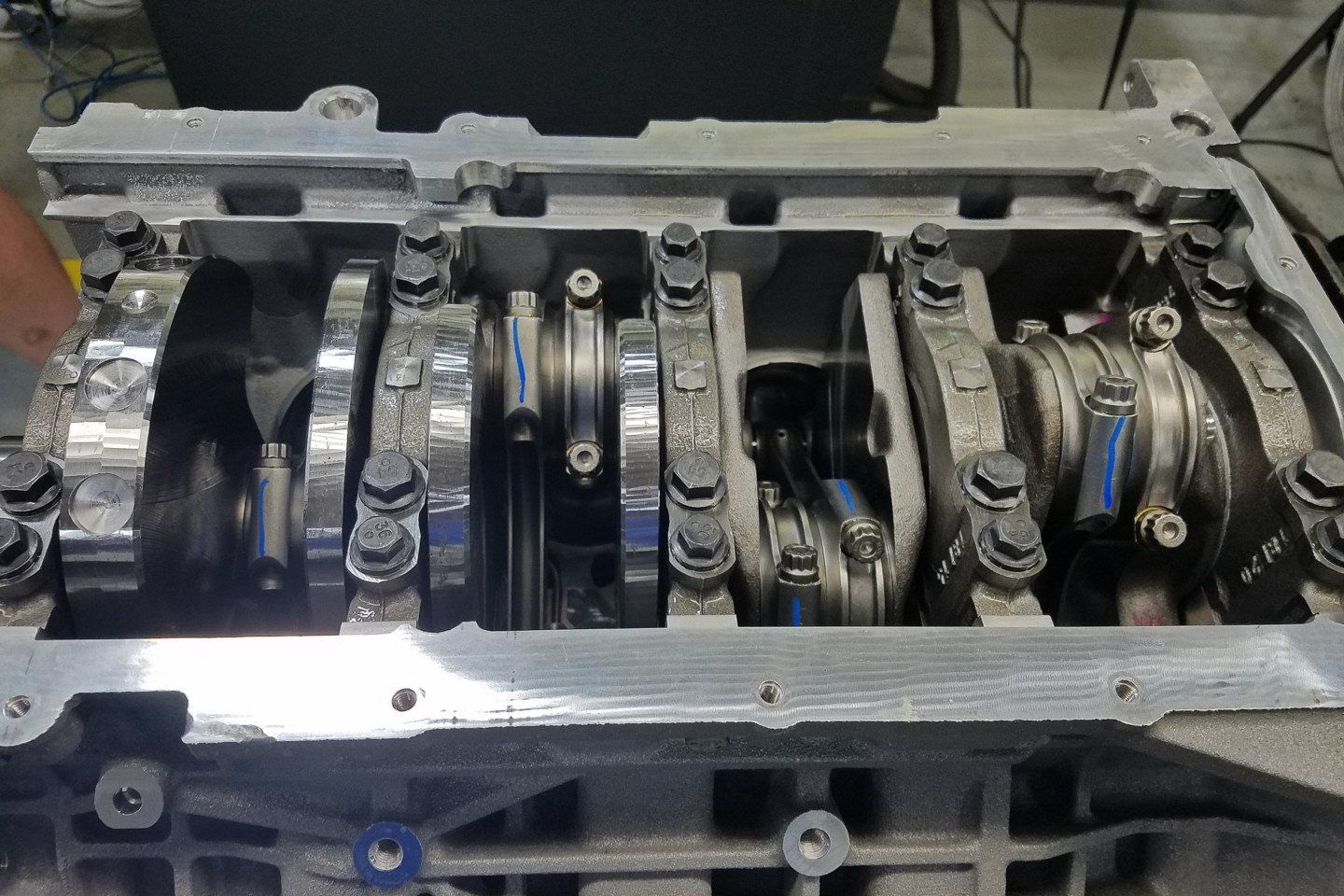

At its core, the Gen-3 Aluminator starts with a production Gen-3 Coyote block. The Gen-3 block has several improvements over the Gen-2 units, mainly in the bores. First is the increase in bore size from 92.2mm (3.630 inches) to 93mm (3.661 inches). Also, it gets the same plasma-spray cylinder liner as the current GT500 Predator engine.

“We’re seeing about 1,200 horsepower being the limit of the spray-bore Coyote blocks,” says Ron Ewert, Performance Engine Engineer for Ford Performance, meaning there is quite a bit of headroom built into the Aluminator right from the get-go. Add to that the production forged-steel 92.7mm (3.650-inch)-stroke crankshaft, which we’ve seen take immense horsepower, and you have the basis of a great 5.0L engine.

The Gen-3 block (right) saw a number of differences over the Gen-2 model, including larger and deeper head bolt holes (identical to the GT500), a more open deck design that allows for a straighter bore, and additional knock sensor locations. Additionally, it features a slightly larger 93mm bore and the Predator’s Plasma Transfer Wire Arc (aka “spray bore”) cylinder liner.

For the pistons, there weren’t any proven off-the-shelf options available, both due to the desired compression ratio of 12.0:1 and the new 93mm bore size. However, Ford Performance has a long-time partner in Mahle, so developing a piston was no problem at all. “On the Coyote dual-fuel engine, they don’t have a DI pocket like the four-cylinder GDI engine family does. The piston crown isn’t unique to the DI fuel system, so that made it easier,” Ewert explains.

In order to handle the power Ford Performance knows will be run through the Aluminator engines, they upgraded the rotating assembly to include Manley forged H-beam connecting rods, and Mahle forged pistons. Paired with the OEM forged crankshaft, the rotating assembly will handle almost anything thrown at it.

.

“We didn’t have to target a bowl, and then work around that to create a crown. There is a little dome there — the compression ratio comes from raising the center height. The valve pockets had to stay about the same location because we went with some added valve lift in Gen-3, so we had to account for that in the pockets.” Add in Mahle’s hard-anodizing process, and the Grafal-coated piston skirts, and you have a solid, reliable piston.

While both Manley and Mahle are proven manufacturers, the new piston and rod combination still had to go through the OEM engine fatigue test, primarily to validate the ring pack and the pistons. While the ring package remains unchanged between the Gen-2 and Gen-3 Aluminator engines, the aftermarket part still had to be validated on the Gen-3’s spray bore liners.

“We perform an engine fatigue test, which is the same test a production engine must pass (~300 hours equivalent to 150,000 miles). We don’t run our test for quite as long as the production programs (100,000-mile equivalence), however, we do run it at elevated power levels,” explains Ewert.

Rounding out the short-block is a set of Ford Performance billet-steel oil pump gears and the factory 10-quart composite oil pan with a Ford Performance oil filter spun on.

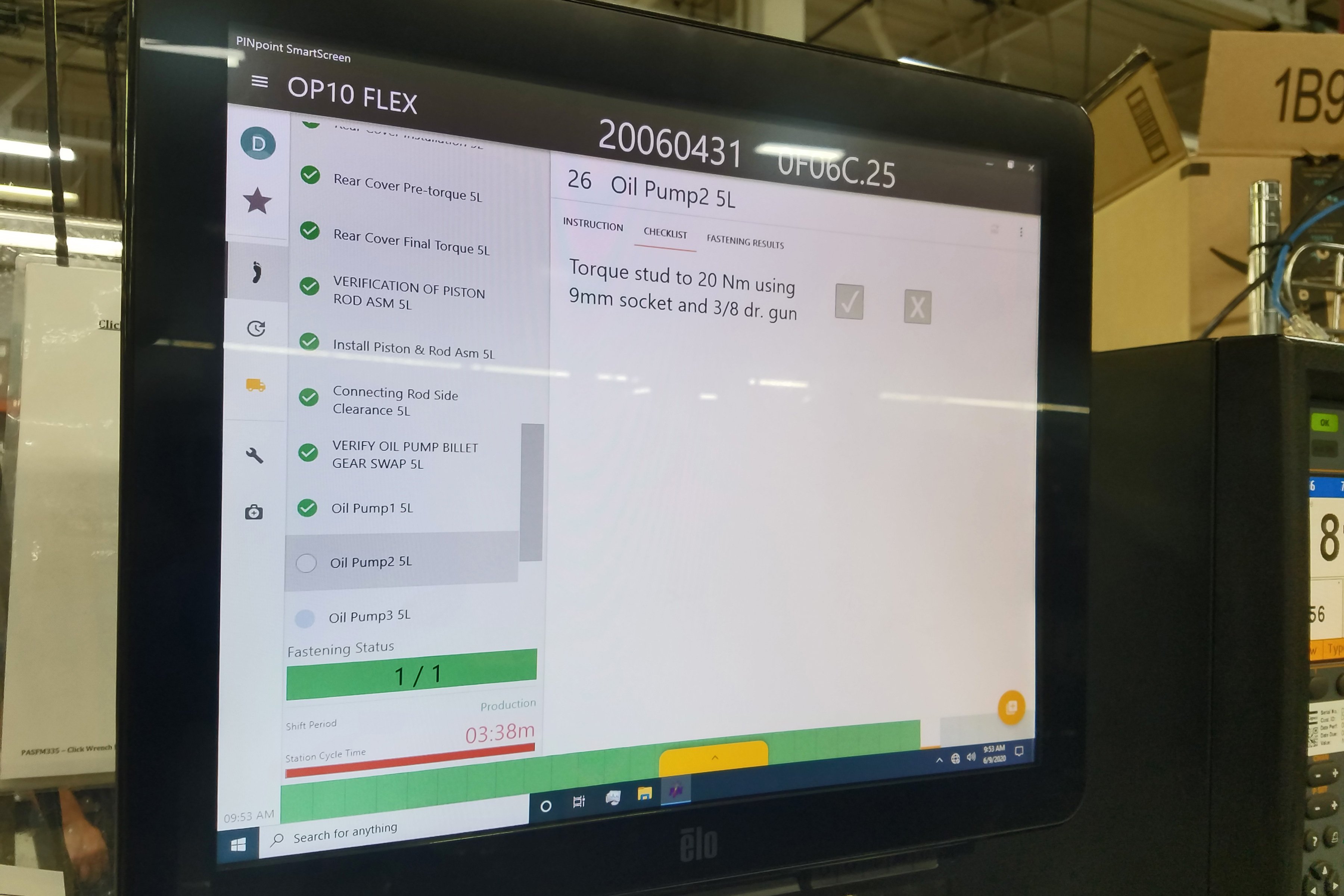

The rotating assembly, like the rest of the engine, gets OEM-level assembly, with the OEM crank rebalanced to a 1,670-gram bobweight, and everything torqued using the high-tech Pin-Point system and marked with a paint pen to indicate that it has been torqued.

Aluminator Top End

Moving up top, the Aluminator enjoys all of the same improvements that the Gen-3 Coyote received, including an improved casting material. Instead of the Gen-2’s 319 aluminum, the Gen-3 uses a newer AS7GU alloy, which adds a small amount of copper to the venerable 356 alloy to increase the strength of the material. “The heads are production pieces. Ford flow modeling is very advanced and typically they flow extremely well in stock form,” says Ewert.

In addition to improved castings, there are a host of improvements in the Gen-3 top end that the Aluminator takes advantage of. New 37.7mm (1.484-inch) intake valves and 32mm (1.260-inch) exhaust valves are slightly larger than the Gen-2’s valves. Improved valvesprings resulted in the factory rev-limiter being raised over Gen-2, and are good for occasional jaunts to the 8,000-rpm mark. However, if you plan to spin above 7,500 rpm on a regular basis, new valvesprings are in your future. Additionally, the Gen-3 enjoys an additional millimeter of lift from the Gen-3 camshafts, from 13mm to 14mm (0.512 inch to 0.551 inch).

The cylinder heads are production Mustang GT Gen-3 Coyote pieces. They feature increased valve sizes, an improved alloy, and incredibly efficient ports, as cast. The factory camshafts also include an extra millimeter of lift.

.

To complement the improved factory valvetrain, Ford Performance brought back a proven component from a previous specialty vehicle – the Boss primary chain tensioners. “Some of the components in the production engine are designed just for production. They are excellent in the capacity of a production engine. But, they become a weakness when you start adding power to it,” explains Ewert

When the production tensioner was “cost-reduced” it went from being made out of steel to aluminum, and also switched to a continuously variable hydraulic-plunger style tensioner. By contrast, the older Boss-style tensioners were made of steel and are a ratcheting design, meaning they only released tension on the chain if manually disassembled. “We decided that even though production feels they don’t need it, it’s a little added insurance for the Aluminator customers,” Ewert says.

.

Topping off the Gen-3 Aluminator is the production Mustang GT tuned composite intake manifold and 80mm throttle body, including the OEM dual-fuel high-pressure lines and injectors. “I wouldn’t say [the dual-fuel system] provided a challenge, just a bit more learning,” Ewert related. “The dual system does allow for further power improvement and another ‘tuning knob’ for the calibrators. You gain the increased compression ratio from direct injection and can swap to larger port fuel injection fuel injectors for more fuel.”

For induction, the Aluminator uses the OEM composite intake manifold, which has been tuned to work with the dual-fuel system and the higher powerband of the Gen-3 Coyote.

.

Baking the Cake

An Aluminator build is more of a transformation than a creation. The process starts with a Ford Performance M50C crate engine (a fresh-off-the-production-line Gen-3 5.0-liter Coyote) delivered to Performance Assembly Solutions in Livonia, Michigan straight from the Essex engine plant. The PAS team is made up of engineers and technicians extremely familiar with Ford’s production standards and methods, and is certified to ISO/IATF 16949, ISO 9001, and ISO 14001 standards.

Once the production engine is set up in a work area, it’s disassembled and the components arranged on a build cart specific to that engine. From there, each component is labeled with a unique barcode that will track that component and all the related specifications throughout the assembly process.

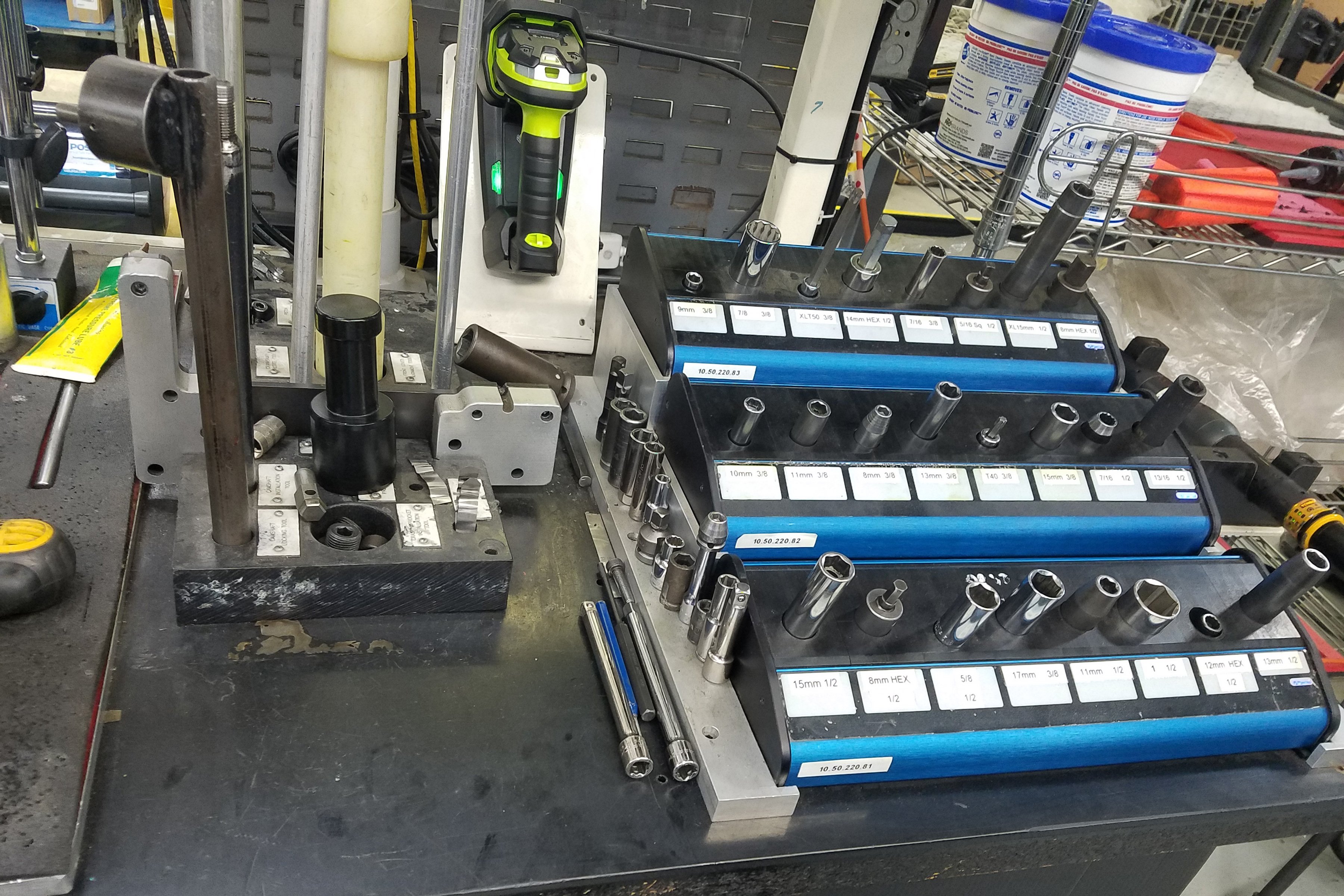

Once all the parts being discarded (rods, pistons, oil pump gears, etc.) are removed from the work area and replaced by the aftermarket pieces on the cart, assembly can begin. Just like any other engine build, the first step is balancing the rotating assembly. However, unlike other engine builds, there are a number of extremely precise, computerized tools which take the place of the click-style torque wrench.

Performance Assembly Solutions uses state-of-the-art computerized assembly sequence, torque, and accountability tools in order to ensure that everything is assembled in order and to the proper torque specs. This level of sophistication is rarely found outside of OEMs.

In addition to setting exact torque values, the computerised tools also require the assembly process to progress in an exact order, not allowing the technician to perform any step out of order. Since there is widespread use of torque-to-yield fasteners in the Coyote, and the factory assembly process generally uses up two of three torque cycles on areas such as the main bearing journals, they are completely replaced in an Aluminator build.

Once the engine is completely assembled, a process known as a “cold test” takes place. The easiest way to describe a cold test would be a dyno, without combustion. More accurately, it’s a cross between a Spintron test and a dyno pull. Key parameters such as oil pressure and cylinder compression, among others, are monitored and evaluated during the run.

“Most Ford engine plants have evolved to cold testing 100-percent of engines,” explains Ewert of the process. “Hot testing is very expensive from an investment point of view and in addition, there are many external regulations involved. Cold testing technology has advanced to levels that allow for an accurate assessment of engine quality.”

“Cold test” technology has evolved to the point where they don’t need combustion to test the performance of various engine systems in order to validate the build. Because the engine has had oil run through all of its systems prior to shipping, it helps with pre-oiling on the first start.

.

If anything during those tests isn’t within the ideal specifications, the engine is taken back to assembly, diagnosed, repaired, and then retested to ensure that every single Aluminator engine is in peak shape when it leaves the PAS facility. “The Aluminator is more than a crate engine,” Goodwin explains. “They get more attention to detail, more specialized parts, and are hand-assembled.”

They say the proof of the pudding is in the pie, and the fact that a single 12.0:1-compression engine configuration can be used for so many forms of motorsport — on pump gas no less — is pretty convincing. “A lot of our drift guys will run the high-compression Aluminator with high boost, but they aren’t under a lot of load as the tires are constantly spinning,” says Ewert. “You can add boost to this one, but you have to be really careful with the higher-compression and boost.”

Once everything is complete and validated, the engine builder signs his name to a build plaque with an electro-pencil, very similar to the SVT Niche-Line plaques Cobra owners are familiar with.

.

For those of you who prefer a lower compression ratio for use with forced-induction, worry not. There is a version of the Gen-3 Aluminator dubbed the “SC” or “supercharged Aluminator” (P/N: M-6007-A50SCB) with a reduced dome volume for a 9.5:1 compression ratio, which is a little more forgiving on the tuning side, if you want to run big boost from whatever power-adder you choose.

Regardless of what compression ratio suits your tastes, there’s no denying that the Gen-3 Aluminator engine is a potent powerplant for anyone wanting the latest and greatest Coyote under the hood of their vehicle.